Shaping Thermal Performance // Architectural Enclosures Graduate Course

Spring 2024

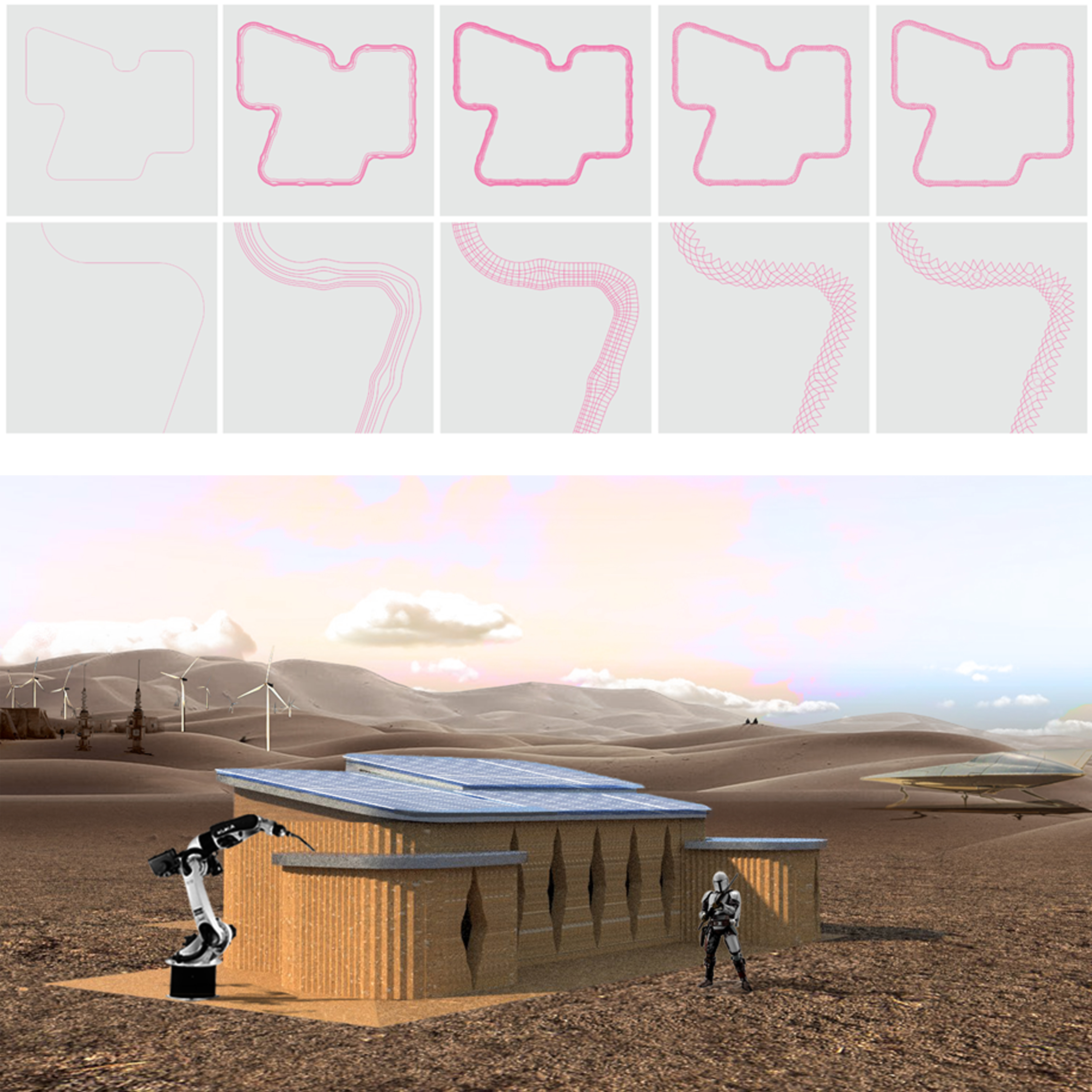

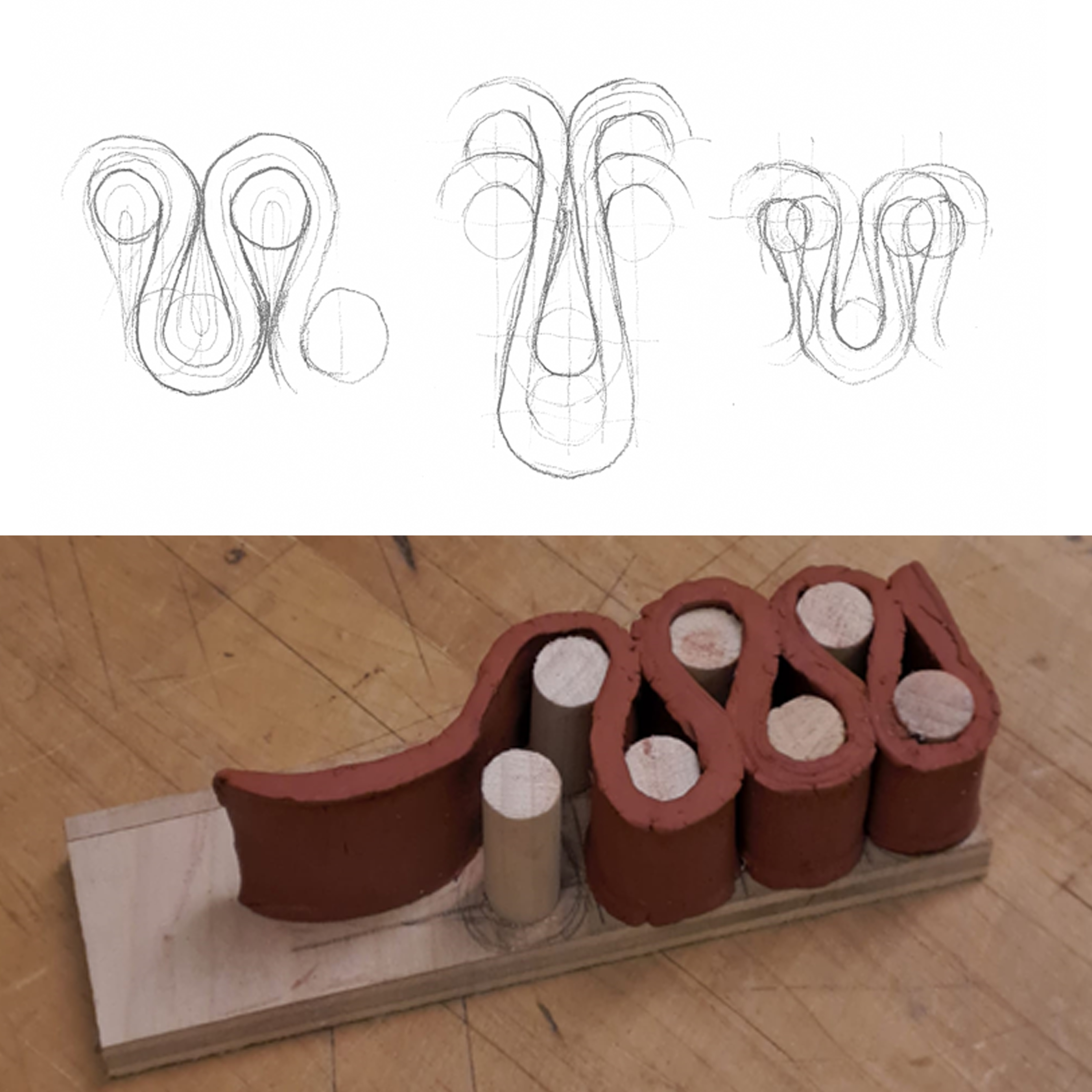

In the context of the climate crisis and rising temperatures, building enclosures must respond to a plurality of requirements –including thermal insulation, heat storage, ventilation, and solar radiation control -- ideally, with minimal embodied carbon and at low cost. While contemporary normative approaches tackle this with assemblies of highly specialized layers, alternative solutions emerge that use geometric specificity to integrate multiple high-performance behaviors in a humble and simplified material palette.

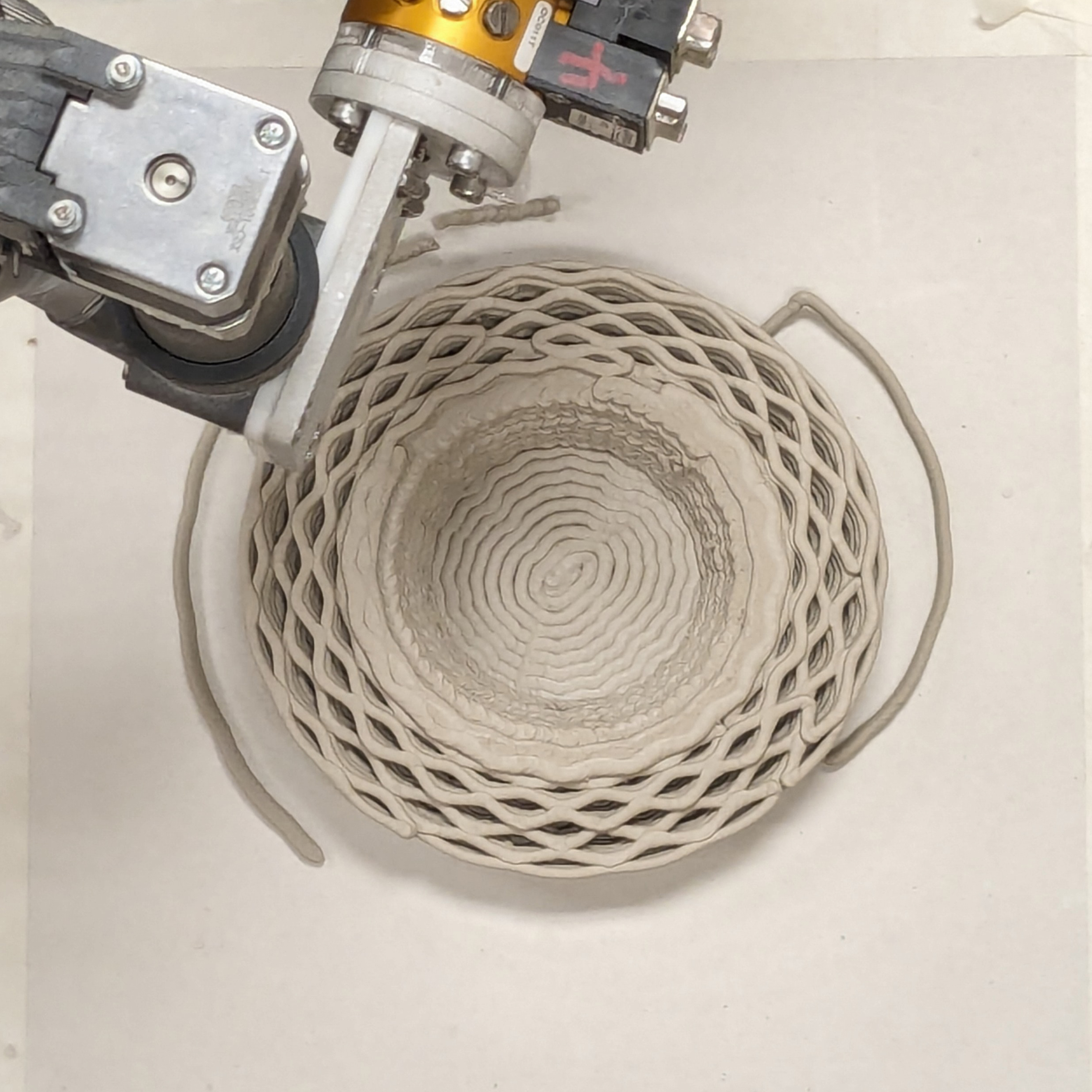

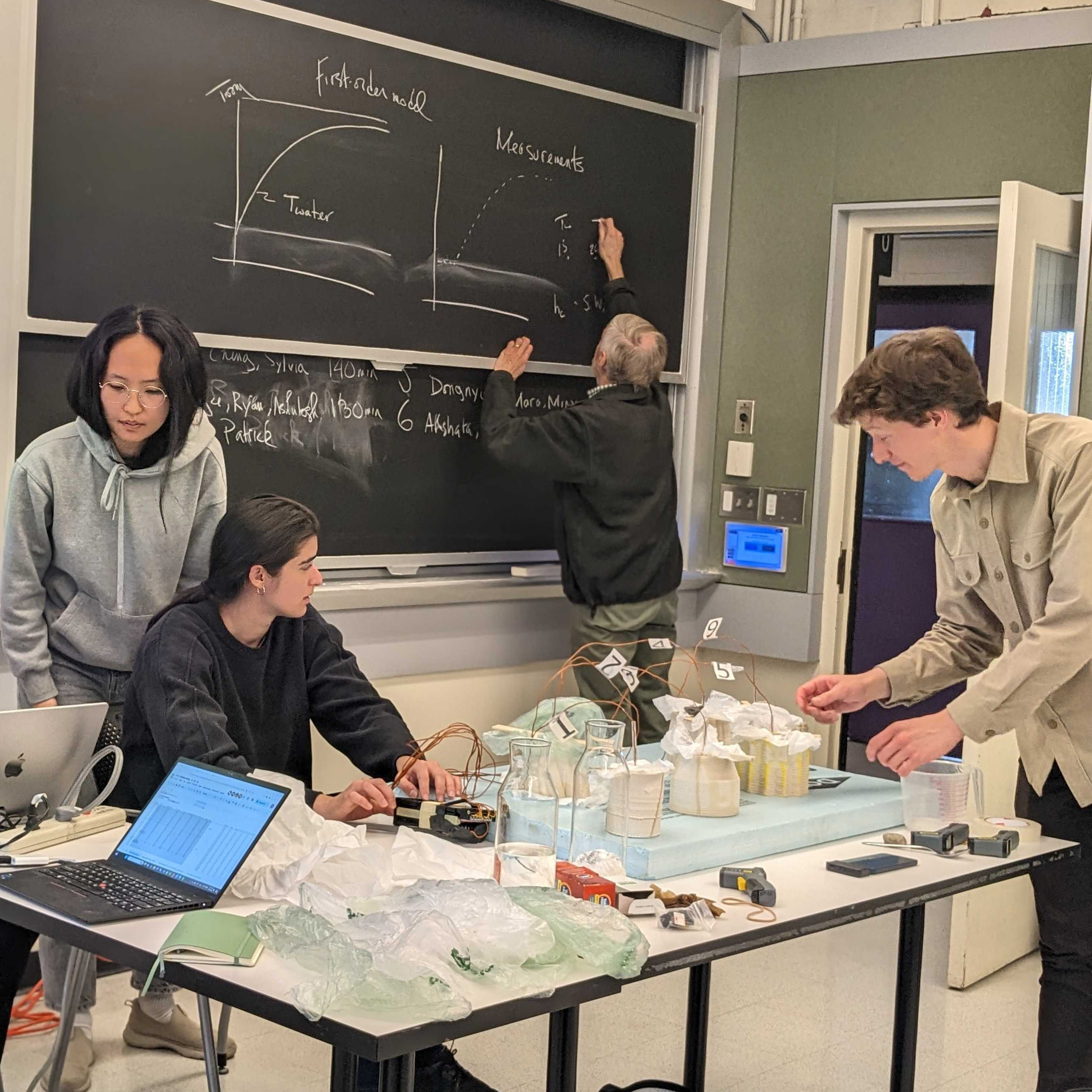

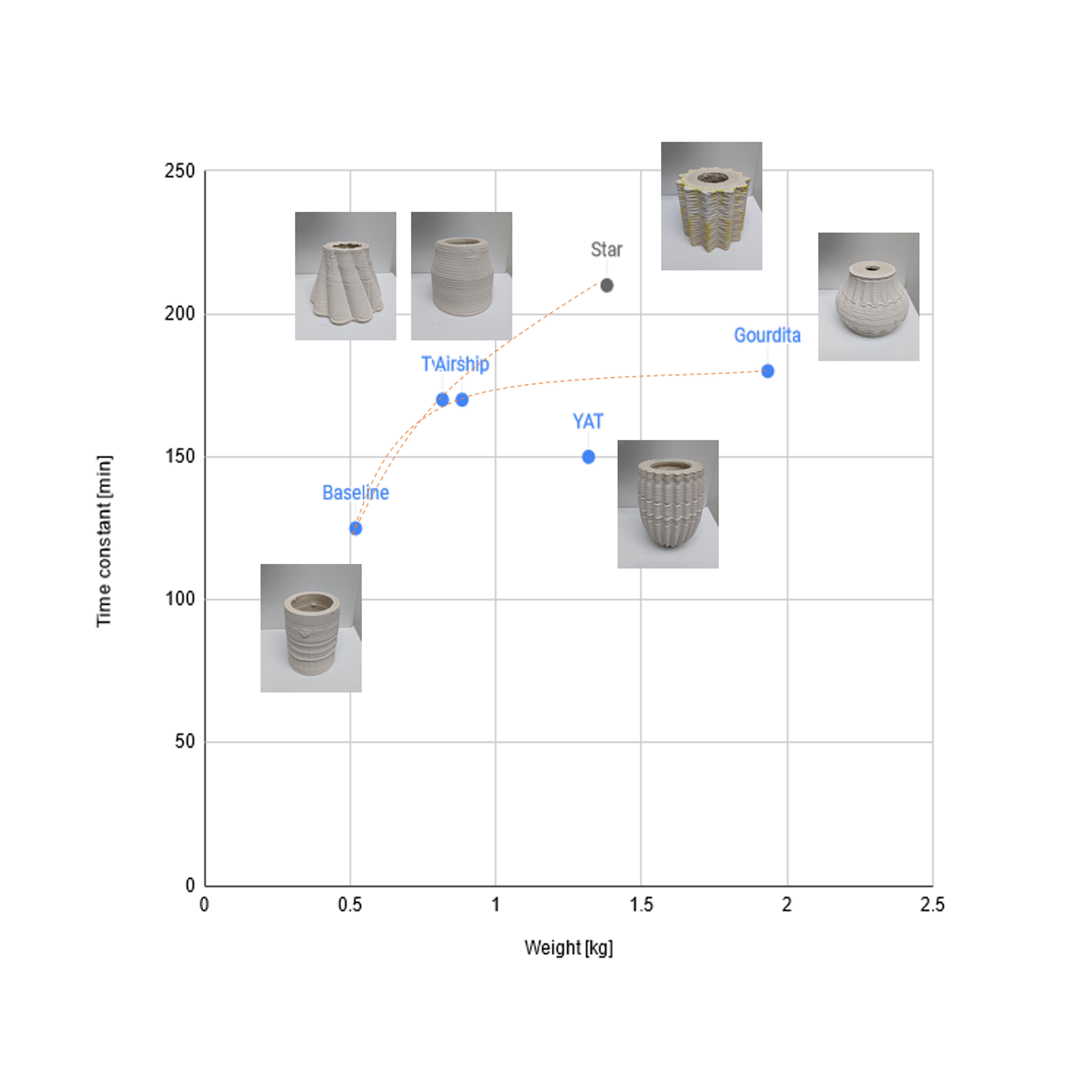

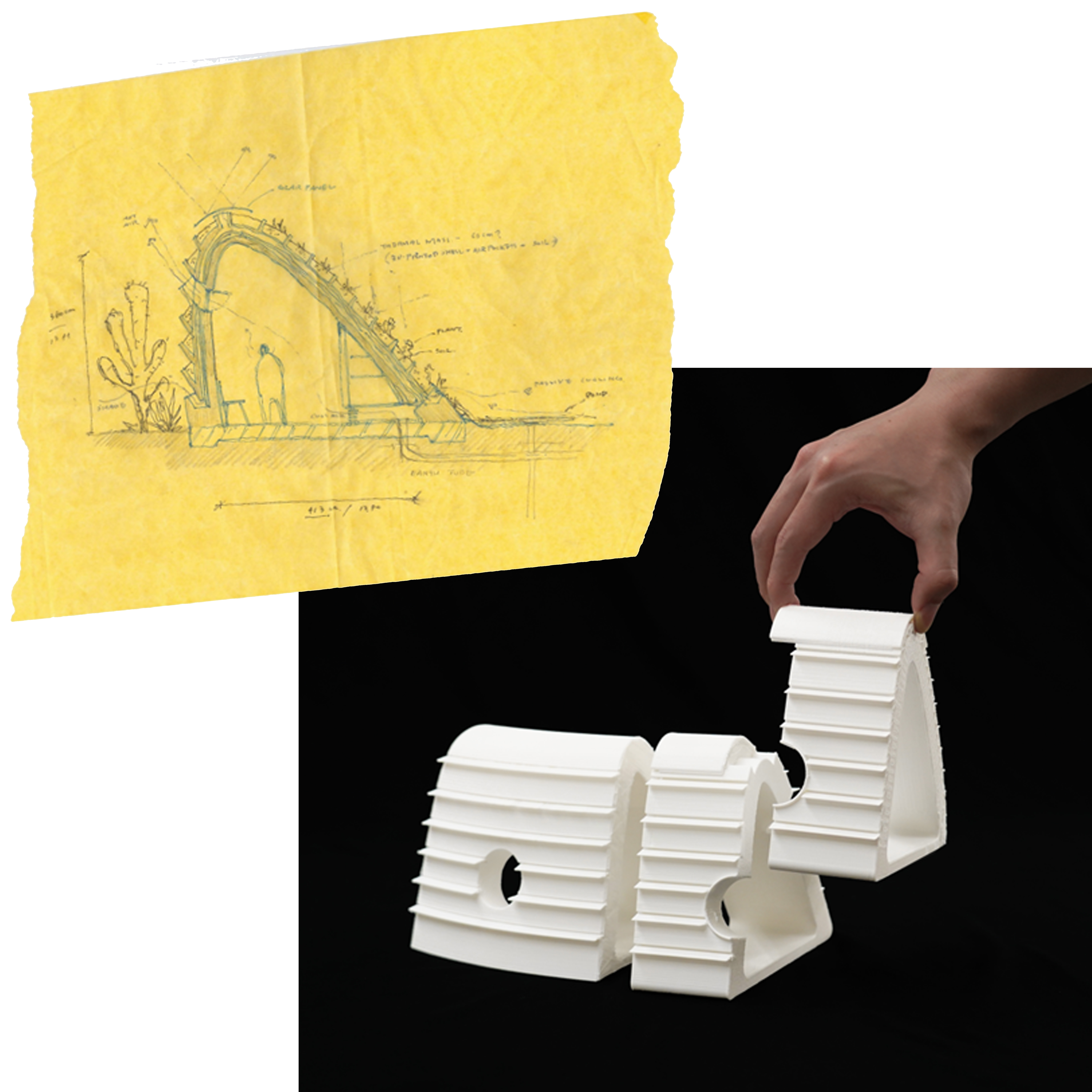

This new workshop explored the use of earthen construction as a low-carbon approach to a heat-resilient architecture that provides cooling solutions in a climate-specific way. The initial exercise challenged students to design a mug (a wall that separates two different environments) to be as lightweight as possible while keeping water cold for as long as possible. The final project consisted of designing an earthen-based wall system supported by digital simulations and physical experiments while exploring its potential impact on architectural expression through its application in a single-story house.

Teaching Team: Eduardo Gascón Alvarez and Caitlin Mueller with support from Professor Les Norford and PhD candidate Sandy Curth

Students: Akshata Atre, Rachel Blowes, Cheng-Hsin Chan, Aisha Cheema, Bryce Crawford, Natasha Hirt, Sylvia Jimenez, Mara Jovanovic, Minyoung Kim, Thomas King, Dong Nyung Lee, Yanyi Liu, Ashutosh Lohana, Patrick Margain, Ryan Otterson, Zhi Ray Wang

Images 1 to 5: Fabrication, firing, and testing of the 3D-printed ceramic mugs. Students experimented with the massing, material distribution, and air pocket location within their designs to achieve a minimal weight (kg) and maximum time constant (h), a measure of the mugs' combined insulation and heat storage properties.

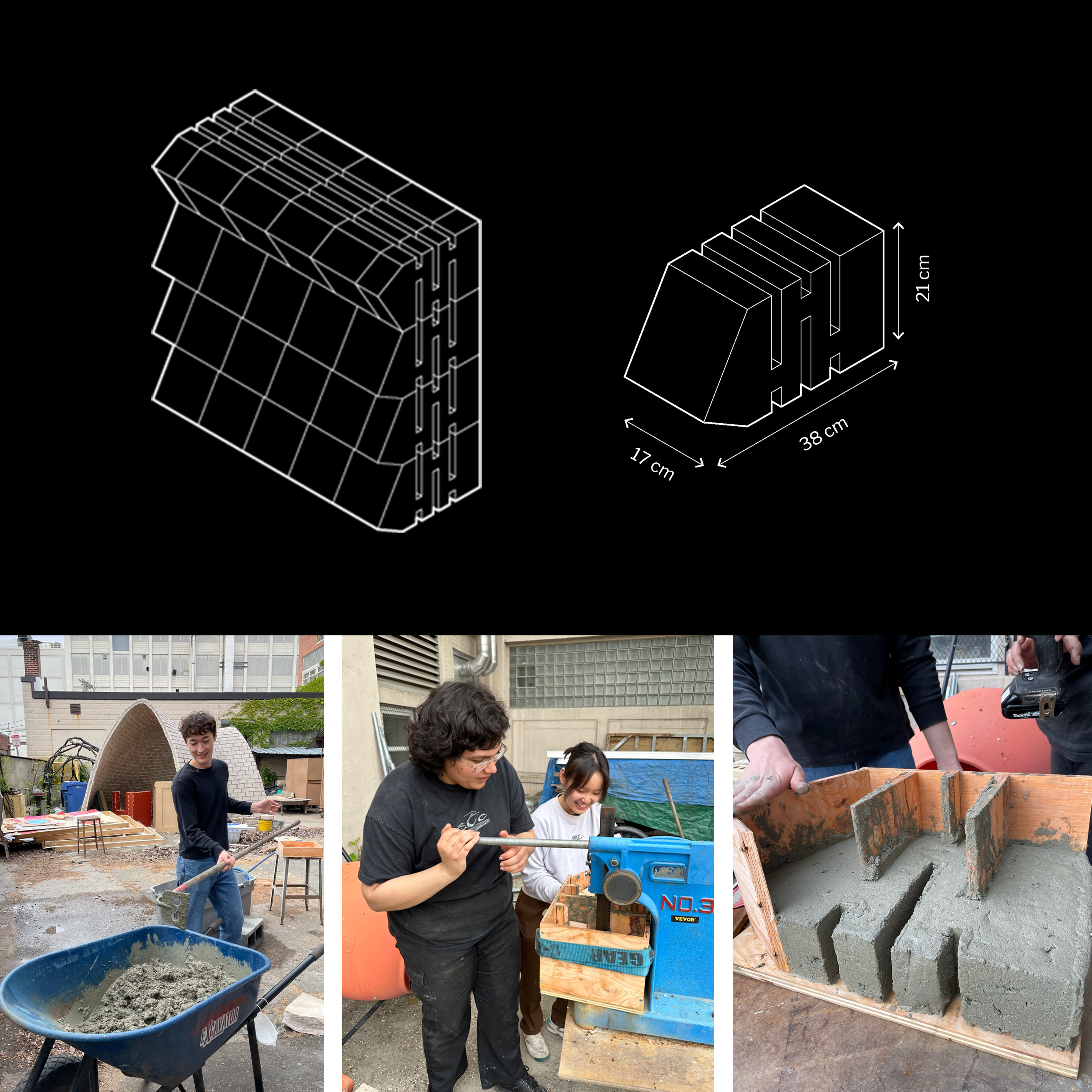

Images 6 to 10: Earth-based wall systems designed for optimal passive cooling performance across three hot climates with varying conditions. The explored fabrication systems ranged from compressed earth blocks to prefabricated 3D-printed modules, multicellular fired clay blocks, on-site printed earth, and wattle and daub.

MIT Accessibility Information