Parametric Waffle Slabs

2022

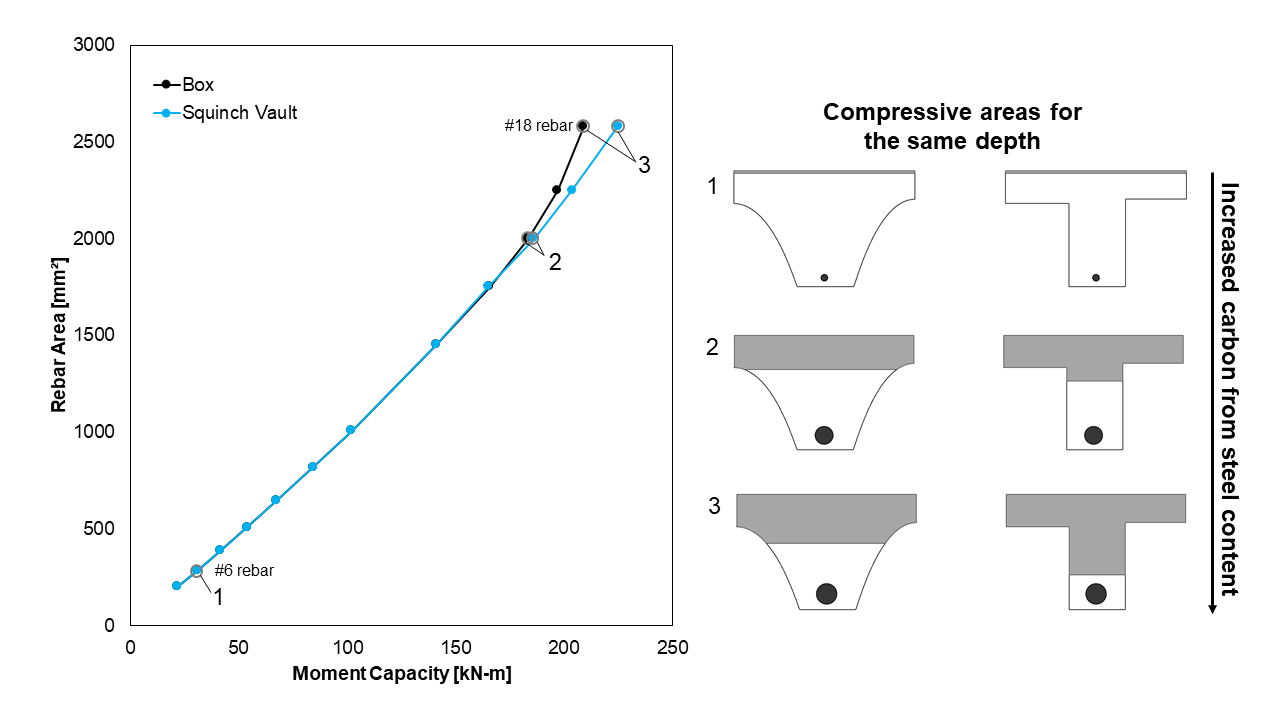

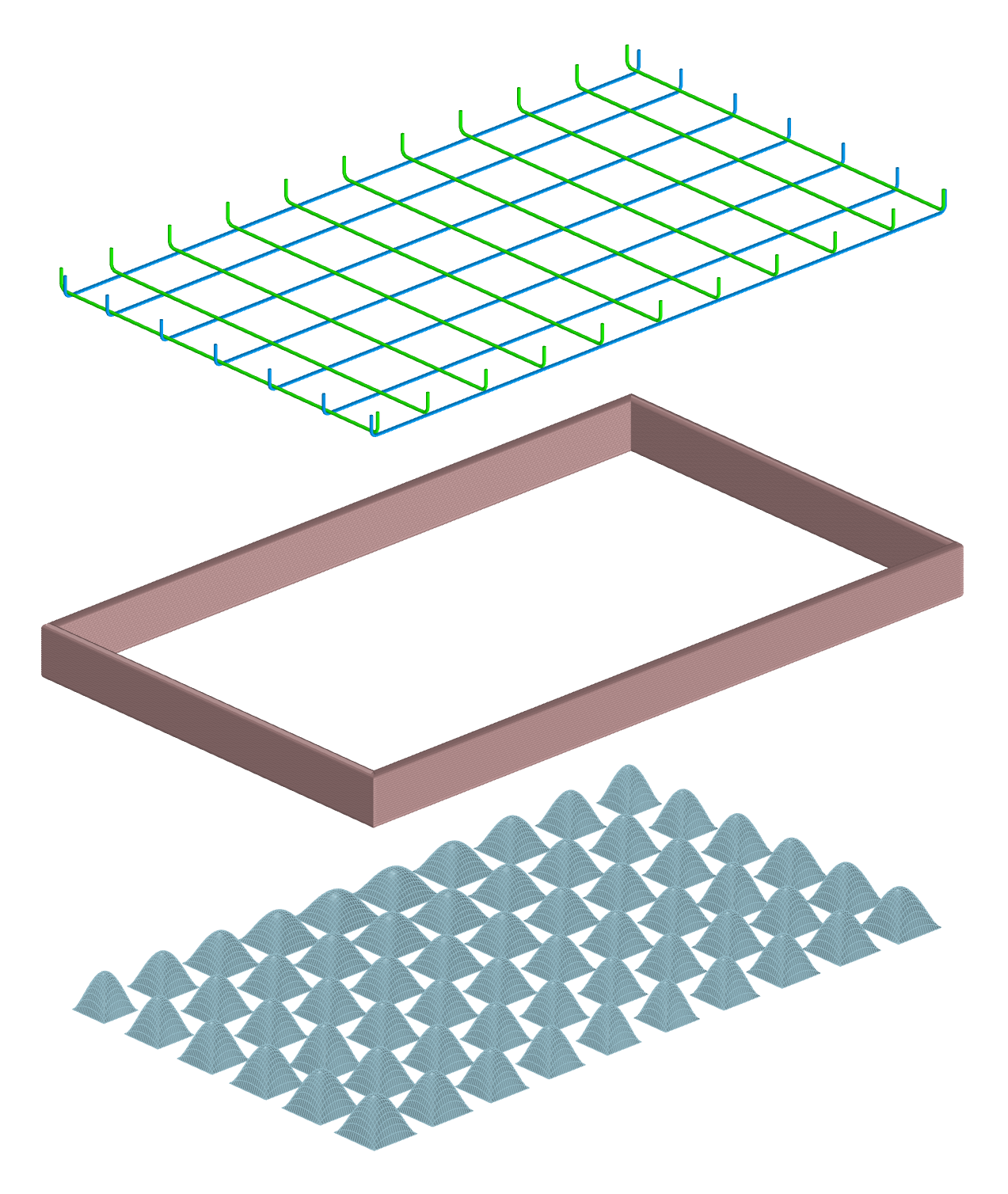

Many researchers have leveraged digital fabrication to reduce the climate impact of high embodied carbon material use. However, horizontal spanning structures (e.g. roofs and floors) remain challenging with respect to energy intensity and structural mass quantity, and existing low-mass construction systems, such as ribbed or waffle slabs, either require proprietary formwork or are particularly labor/cost intensive. Recent advances in mass customization through digital fabrication have enabled efficient, formwork free methods for concrete construction. This work presents a hybrid design methodology using FEA simulation and closed-form approaches that allow for the shape optimization of two-way ribbed spanning systems in response to spatially varied structural demands. We utilize a LSAM (Large Scale Additive Manufacturing) system paired with a nonplanar toolpath optimization workflow to 3D print lost concrete formwork for a cast-in-place, shape optimized waffle slab. The geometric freedom of additive manufacturing allows for the wide range of void sizes specified by the optimization to be printed without significant increase in labor and material costs. With the simulation approaches outlined here and tests printed with an industry partner (TAM) we show a flexible methodology for widely customizable cast-in-place waffle slabs. This novel construction automation approach is promising for a wide range of construction applications, broadening the scope of what can be printed on site.

Project team: Ashley Hartwell and Sandy Curth, Tim Brodesser, Caitlin Mueller

Open Access Publication here.

Citation:

[1

Alexander Curth, Ashley Hartwell, Tim Brodesser, and Caitlin T. Mueller, “Parametric waffle slabs: Optimal geometry materialized with additive construction,” in International Association for Shell and Spatial Structures 2022, Beijing, Aug. 2022, pp. 3183–3193.

MIT Accessibility Information